LT XLPE Cables

Price 10 INR/ Meter

MOQ : 100 Meters

LT XLPE Cables Specification

- Impedance

- Low

- Locking Type

- Non-locking

- Diameter

- Varies (as per size)

- Dielectiric Strength

- >24 kV/mm

- Armored Material

- Steel/Aluminum (if armored)

- Rated Temperature

- 90C

- Number of Conductor

- 1, 2, 3, 3.5, 4 or as specified

- Features

- High electrical strength, resistance to chemicals and abrasion, flame retardant

- Conductor Shape

- Circular

- Operating Temperature

- -10C to +90C

- Install Type

- Direct burial/Conduit/Trunking

- Conductor Type

- Stranded/Single

- Usage & Applications

- Suitable for underground, industrial, and outdoor installations

- Core Material

- Copper

- Cable Type

- Low Tension Power Cable

- Tensile Strength

- >15 MPa

- Core Number

- 14 (as per specification)

- Insulation

- Cross-linked Polyethylene

- Weight

- Variable, depends on size and length

- Product Type

- LT XLPE Cables

- Length

- Up to 1000 meters

- Voltage

- High Voltage Volt (v)

- Insulation Material

- XLPE

- Application

- Power transmission and distribution, industrial installations

- Conductor Material

- Copper

- Jacket Material

- PVC

- Storage Temperature

- -20C to +60C

- Connector Color

- Black/Red/Blue (as required)

- Shield Material

- Aluminium Tape

- Jacket Color

- Black

- Dimension (L*W*H)

- Custom as per requirement

- Material

- Copper & XLPE & PVC jacket

- Color

- Black

- Size

- 1.5 sq.mm to 400 sq.mm

LT XLPE Cables Trade Information

- Minimum Order Quantity

- 100 Meters

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Meters Per Month

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

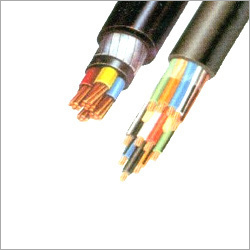

About LT XLPE Cables

LT XLPE Cables are commonly used in underground or overhead power transmissions. They find wide application in thermal power plants, power transmission industries and many other electric & switchgear industries. These are made up in tandem with defined parameters using latest technology and quality materials. These are safe to use as they have fine outer coating with excellent conductivity. Offered LT XLPE Cables are widely appreciated for their high performance, optimum strength, less maintenance and cost-effectiveness.

Versatile Application

LT XLPE Cables are engineered for flexibility, accommodating power transmission and distribution needs in both indoor and outdoor environments. They are particularly suited for industrial facilities, underground laying, and areas requiring high resistance to mechanical stress. Their adaptable design allows for use in direct burial, conduit, or trunking methods, ensuring safe and effective energy delivery.

Superior Safety and Compliance

Safety is assured with flame retardant properties aligned with IS:10462, and the cables provide excellent resistance to chemicals, UV rays, and abrasion. Compliant with IS:7098 (Part 1), IEC 60502-1, and RoHS, these cables meet stringent international and national standards, facilitating reliable operation even in harsh conditions.

Rugged Construction Features

Manufactured using copper conductors and XLPE insulation, these cables offer impressive electrical and mechanical performance. The tough PVC jacket and optional steel or aluminum armoring further enhance durability, making them suitable for demanding environments. Variable core numbers, thicknesses, and lengths allow customization to specific project needs.

FAQs of LT XLPE Cables:

Q: How should LT XLPE Cables be installed for optimal performance?

A: Install LT XLPE Cables following IS:1255 recommendations for laying depth and ensure the minimum bending radius is at least 12 times the cables overall diameter. These cables are suitable for direct burial, conduit, or trunking, making them ideal for both indoor and outdoor applications.Q: What standards and certifications do LT XLPE Cables comply with?

A: These cables comply with IS:7098 (Part 1), IEC 60502-1, and meet RoHS environmental standards. Flame retardant performance is in accordance with IS:10462, ensuring safety and reliability in power transmission scenarios.Q: When is it beneficial to use LT XLPE Cables over other power cables?

A: LT XLPE Cables are beneficial when high electrical strength, flame retardance, excellent UV and chemical resistance, and durability are required. They are especially suitable for underground, industrial, and outdoor installations, or where minimal maintenance and high performance are essential.Q: Where can LT XLPE Cables be applied?

A: These cables are widely used in power transmission and distribution networks, industrial plants, underground installations, and outdoor environments, thanks to their robust construction and resistance to environmental factors.Q: What is the process for specifying or ordering LT XLPE Cables?

A: To specify or order, determine the required size (1.5 sq.mm to 400 sq.mm), number of cores, armoring type, and sheath color. Custom dimensions and cable lengths (up to 1000 meters) are available upon request to suit varying project requirements.Q: What are the main benefits of using XLPE insulation in these cables?

A: XLPE insulation offers high dielectric strength exceeding 24 kV/mm, thermal endurance up to 90C (continuous) and 250C (short circuit), and remarkable resistance to moisture, chemicals, and abrasion, leading to longer cable lifespan and lower maintenance.Q: How does the cable construction enhance performance and safety?

A: The combination of stranded or single copper conductors, XLPE insulation, robust PVC jacket, and optional steel/aluminum armoring delivers excellent electrical conductivity, mechanical strength, and flame retardance, thus protecting circuits and ensuring reliable operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electric Cables Category

PVC CABLES

Price 250 INR / Meter

Minimum Order Quantity : 1000 Meters

Jacket Material : PVC

Conductor Material : Aluminum

Conductor Shape : Other

PVC Insulated Electric Cables

Price 10 INR / Meter

Minimum Order Quantity : 100 Meters

Jacket Material : PVC

Conductor Material : Copper

Product Type : Electric Cable

Conductor Shape : Round

LT Electrical Cables

Price 10 INR / Meter

Minimum Order Quantity : 100 Meters

Jacket Material : PVC

Conductor Material : Copper

Product Type : Electrical Cables

Conductor Shape : Round

FRLS Cables

Price 10 INR / Meter

Minimum Order Quantity : 100 Meters

Jacket Material : PVC

Conductor Material : Copper

Product Type : Cables

Conductor Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS